|

|

| Main -> Heating units, refrigerating units -> Temperature controllers -> Heating cabinets, drying cabinets, sterilizers, microwaves |

| Universal Ovens, Memmert |

The oven generation with the unique ControlCOCKPIT for quick and intuitive operation. For a wide portfolio of applications, ideally in temperature ranges above +50°C. UN and UF ovens with SingleDISPLAY

N = Natural convection F = Forced air circulation SingleDISPLAY: ControlCOCKPIT with one TFT color graphic display - Available parameters on the ControlCOCKPIT: temperature (Celsius or Fahrenheit), fan speed, exhaust air flap position, program runtime, time zones, daylight-saving time

- One temperature sensor Pt100 DIN class A in a 4-wire circuit

- Software AtmoCONTROL for data read out and programming of the data logger via Ethernet interface (90 days test version as free download).

- Ethernet interface on the rear of the appliance for reading out the protocol log

- Double overtemperature protection: Electronic temperature monitoring with freely adjustable monitoring temperature, mechanical temperature limiter TB acc. to DIN 12 880

UNplus and UFplus ovens with TwinDISPLAY

N = Natural convection F = Forced air circulation TwinDISPLAY: ControlCOCKPIT with two TFT color graphic displays - Available parameters on the ControlCOCKPIT: temperature (Celsius or Fahrenheit), fan speed, exhaust air flap position, program runtime, time zones, daylight-saving time

- Two Pt100 sensors DIN class A in a 4-wire circuit for mutual monitoring, taking over functions in case of an error

- Software AtmoCONTROL on USB pen drive for programming, managing and transferring of programs via Ethernet interface or USB port

- HeatBALANCE function for application specific adjustment of heating power distribution (balance) between the upper and lower heating groups in an adjustment range between -50% and +50%

- ControlCOCKPIT with USB port for uploading programs, reading out protocol logs, activating the User-ID function

- Displaying of already logged protocol data on the ControlCOCKPIT (max 10,000 values correspond to approx. 1 week)

- Ethernet interface on the rear of the appliance for reading out the protocol log and for uploading and implementing programs and for online logging

- Multiple overtemperature protection: Electronic temperature monitoring TWW/TWB (protection class 3.1 or 2 resp. 3.3 for units with active cooling) and mechanical temperature limiter TB (protection class 1) acc. to. DIN 12 880, AutoSAFETY automatically adjusts to the set value within a freely adjustable tolerance range. Setting individual MIN / MAX values for over/undertemperature

Basic equipment: - PID microprocessor regulation with integrated autodiagnosis system

- Interior made of stainless steel, reinforced by deep drawn ribbing, material no. 1.4301 (ASTM 304), for integraton of the ceramic-and-metal-coated large-area heating

- Structured stainless steel housing, rear of zinc-plated steel

- ControlCOCKPIT for operation and adjustment of all parameters

- High-temperature connectors on the rear of the appliance for single-phase power connection according to country specific systems and IEC standards

- Internal data logger with a storage capacity of at least 10 years

- German, English, French, Spanish language settings available on the ControlCOCKPIT

- Digital timer, adjustable between 1 minute and 99 days

- The SetpointWAIT function guarantees that the process time does not start until the set temperature is reached at all measuring points - optional for temperature values recorded by the freely positionable Pt100 sensors inside the chamber

- Adjustment of three calibration values for temperature and additional appliance specific parameters directly at the ControlCOCKPIT

Technical data: | |

Interior: | made of stainless steel No. 1.4301 (ASTM 304), high stability by deep-drawn ribbing and easy to clean |

Housing (exterior): | textured stainless steel, rear zinc-plated steel: (size 450 to 1060 on lockable rolls) |

Temperature range: | from 30°C (however, at least 5°C above room temperature) up to +300°C |

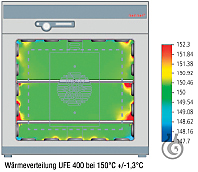

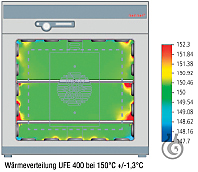

Temperature deviations: | at 150°C accuracy ±0.5°C, uniformity at 150°C ±3°C |

Electrical supply: | 230 V (±10%) up to model size 260, from model size 450 three-phase current 400 V 3 ph N (CEE plug, 16-A version). Other voltages to special order. |

Available models and sizes with fully insulated stainless steel door:

Series UN1) 2)

With natural air circulation and microprocessor PID control.

| Type | Outer W × H × D

mm | Inner W × H × D

mm | Vol. approx.

l | Wght approx.

kg | P rating approx.

W | Order No. | |

| UN30 | 585×704×434 | 400×320×250 | 32 | 48 | 1600 | 10 26 03030 | |

| UN55 | 585×784×514 | 400×400×330 | 53 | 57 | 2000 | 10 26 03055 | |

| UN75 | 585×944×514 | 400×560×330 | 74 | 66 | 2500 | 10 26 03075 | |

| UN110 | 745×864×584 | 560×480×400 | 108 | 78 | 2800 | 10 26 03110 | |

| UN160 | 745×1104×584 | 560×720×400 | 161 | 96 | 3200 | 10 26 03160 | |

| UN260 | 824×1183×684 | 640×800×500 | 256 | 110 | 3400 | 10 26 03260 | |

| (1) | UN450 | 1224×1247×784 | 1040×720×600 | 449 | 170 | 58003) | 10 26 03450 | |

| UN750 | 1224×1726×784 | 1040×1200×600 | 749 | 217 | 70003) | 10 26 03750 | |

Series UF1) 2)

With natural air circulation and microprocessor PID control.

| Type | Outer W × H × D

mm | Inner W × H × D

mm | Vol. approx.

l | Wght approx.

kg | P rating approx.

W | Order No. | |

| UF30 | 585×704×434 | 400×320×250 | 32 | 48 | 1600 | 10 26 05030 | |

| UF55 | 585×784×514 | 400×400×330 | 53 | 57 | 2000 | 10 26 05055 | |

| UF75 | 585×944×514 | 400×560×330 | 74 | 66 | 2500 | 10 26 05075 | |

| UF110 | 745×864×584 | 560×480×400 | 108 | 78 | 2800 | 10 26 05110 | |

| UF160 | 745×1104×584 | 560×720×400 | 161 | 96 | 3200 | 10 26 05160 | |

| UF260 | 824×1183×684 | 640×800×500 | 256 | 110 | 3400 | 10 26 05260 | |

| UF450 | 1224×1247×784 | 1040×720×600 | 449 | 170 | 58003) | 10 26 05450 | |

| (4) | UF750 | 1224×1726×784 | 1040×1200×600 | 749 | 217 | 70003) | 10 26 05750 | |

| UF1060 | 1224×1726×1035 | 1040×1200×850 | 1060 | 305 | 70003) | 10 26 06161 | |

Series UNplus1) 2)

With natural air circulation and microprocessor PID control.

| Type | Outer W × H × D

mm | Inner W × H × D

mm | Vol. approx.

l | Wght approx.

kg | P rating approx.

W | Order No. | |

| UN30plus | 585×704×434 | 400×320×250 | 32 | 48 | 1600 | 10 26 08030 | |

| UN55plus | 585×784×514 | 400×400×330 | 53 | 57 | 2000 | 10 26 08055 | |

| UN75plus | 585×944×514 | 400×560×330 | 74 | 66 | 2500 | 10 26 08075 | |

| UN110plus | 745×864×584 | 560×480×400 | 108 | 78 | 2800 | 10 26 08110 | |

| (2) | UN160plus | 745×1104×584 | 560×720×400 | 161 | 96 | 3200 | 10 26 08160 | |

| UN260plus | 824×1183×684 | 640×800×500 | 256 | 110 | 3400 | 10 26 08260 | |

| UN450plus | 1224×1247×784 | 1040×720×600 | 449 | 170 | 58003) | 10 26 08450 | |

| UN750plus | 1224×1726×784 | 1040×1200×600 | 749 | 217 | 70003) | 10 26 08750 | |

Series UFplus1) 2)

With enforced air circulation and microprocessor PID control.

| Type | Outer W × H × D

mm | Inner W × H × D

mm | Vol. approx.

l | Wght approx.

kg | P rating approx.

W | Order No. | |

| UF30plus | 585×704×434 | 400×320×250 | 32 | 48 | 1600 | 10 26 06030 | |

| UF55plus | 585×784×514 | 400×400×330 | 53 | 57 | 2000 | 10 26 06055 | |

| UF75plus | 585×944×514 | 400×560×330 | 74 | 66 | 2500 | 10 26 06075 | |

| (3) | UF110plus | 745×864×584 | 560×480×400 | 108 | 78 | 2800 | 10 26 06110 | |

| UF160plus | 745×1104×584 | 560×720×400 | 161 | 96 | 3200 | 10 26 06160 | |

| UF260plus | 824×1183×684 | 640×800×500 | 256 | 110 | 3400 | 10 26 06260 | |

| UF450plus | 1224×1247×784 | 1040×720×600 | 449 | 170 | 58003) | 10 26 06450 | |

| UF750plus | 1224×1726×784 | 1040×1200×600 | 749 | 217 | 70003) | 10 26 06750 | |

| UF1060plus | 1224×1726×1035 | 1040×1200×850 | 1060 | 305 | 70003) | 10 26 06162 | |

1) External dimensions: Depth without door handle, depth of door handle 56 mm

2) Inner dimensions (depth): On models with air turbine the depth is reduced by 39 mm for the fan.

3) With 400 V and 3 × 230 V o.N., 50/60 Hz. All universal ovens comply with the strict requirements of DIN 12 880: 2007-05

Stainless steel grid (standard version: size 30, 55 and 1060: 1 piece, size 75 to 750: 2 pieces)

Stainless steel shelves, perforated

Stainless steel shelves, perforated

Stainless steel shelves

Stainless steel shelves, non-perforated, 15 mm rim

Special equipment

| Article | Order No. | |

| IQ document, OQ/PQ checklist | 10 26 03802 | |

| IQ check list with works test data for oven, OQ/PQ check lists as support for validation by customer | |

| IQ/OQ document, PQ checklist (size 30) | 10 26 03803 | |

| IQ/OQ document with works test data for oven, incl. temperature distribution measurement for a freely selectable temperature value. 9 measuring points acc. to DIN 12 880: 2007-05 (other temperature values available on request), PQ check list as support for validation by customer | |

| IQ/OQ document, PQ checklist (from size 55 on) | 10 26 03804 | |

| IQ/OQ document with works test data for oven, incl. temperature distribution measurement for a freely selectable temperature value. 27 measuring points acc. to DIN 12 880: 2007-05 (other temperature values available on request), PQ check list as support for validation by customer | |

| USB ethernet adapter | 10 26 03810 | |

| Ethernet cable, 5 m | 10 26 03811 | |

| for computer interface | |

| USB user ID stick | 10 26 03812 | |

| User authorization license for oven (user ID program) on Memory-Stick for units with TwinDISPLAY | |

| USB stick with documentation software AtmoCONTROL | 10 26 03813 | |

| and operating instructions for units with SingleDISPLAY (comprised in the standard scope of delivery for units with TwinDISPLAY) | |

Further special equipment, such as full-sight glass door, entry ports, Pt100 for external temperature recording, a.s.o. upon request.

We reserve the right to make changes in technical specifications. Dimensions subject to confirmation.

All performance data are typical mean values for serial devices. |

|

|