|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Main -> Heating units, refrigerating units -> Temperature controllers -> Vacuum cabinets | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Vacuum Ovens, Memmert | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

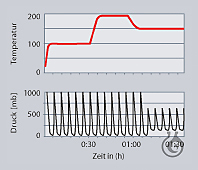

| Series VO

Fuzzy-supported process controller for volume-optimized temperature control - individually for each shelf - programmable for up to 40 ramps (Multi-Level-Controlling), adapting its performance to the volume (local temperature sensing ) for each thermoshelf. Digital display of actual temperature traceable individually for each thermoshelf (Multi-Level-Overtemperature Protection MLOP), activated at 3°C above the setpoint. 7-day-program-timer with real time clock and timer (for residual time - programmable for each ramp segment). Multiple overtemperature protection, undertemperature alarm and gliding over/undertemperature monitoring linked automatically to the setpoint (ASF = Auto-Safety Function) at a preselected tolerance margin. Autodiagnostic system for rapid fault identification. Menu guidance by 8-digit alphanumerical display. Setpoints and actual temperature recording with MEMory Card XL up to 40 ramps. Ring store 1024 kB for long-term documentation of all relevant data. Interface USB with software "Celsius" with advanced features for temperature and pressure. 2 connection options for thermoshelves

External dimensions: depth without door handle, depth of door handle 38 mm The cooled vacuum drying oven VO200cool with 29 liters and the VO400cool with 49 liters interior volume have a temperature range of +5°C to +90°C. For cooling, a compact, energy-saving and highly precise Peltier cooling unit was integrated. Thus, the cooled Memmert vacuum drying units achieve an even temperature distribution over the entire temperature range with a maximum deviation of ±1 K.

External dimensions: depth without door handle, depth of door handle 38 mm, incl. Peltier cooler Switch to inert gas Programmable and digitally controlled inlet for inert gas with a flow rate reduction.

(Standard accessories for VO200cool/VO400cool) Contains the option of inert gas inlet, printer port, one (size 200) or two (size 400/500) additional connections for thermoshelves, one extra thermoshelf (size 400/500) and one drip tray.

Accessories 3 Additional thermoshelves aluminium anodized, material 3.3547 (ASTM B209); standard version: 1 piece

3 Additional thermoshelves stainless steel No. 1.4404 (ASTM 316 L) for particularly corrosion-prone materials

Removable bottom drip tray stainless steel material 1.4404 (ASTM 316 L)

Noise absorbing vacuum pump module without pump With antivibration metal plate at the bottom to accommodate the vacuum pump, including full-sight glass door, socket, signal cable and connecting hose to the vacuum oven.

4 Noise absorbing vacuum pump module with pump Ditto, 230 V, 50 Hz (other voltages upon request)

Chemically resistant vacuum pump With PTFE double diaphragm, with automatic purge process through controller of vacuum oven (signal cable and vacuum connection - see below - are compulsory).

Accessories

Checklists

5 Subframe Tubular steel, black enamelled (for stacking unit consisting of vacuum oven and pump module, total height: 1650 mm)

We reserve the right to make changes in technical specifications. Dimensions subject to confirmation. |     |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||