|

|

| Main -> Volumetry -> Dosing devices -> Dispensers |

| Dispensette® Dispensers, BRAND |

The Dispensette® bottle-top dispensers cover a very wide range of applications and have scored best marks for dosing accurate volumes of even aggressive media.

All models are conformity certified to DIN 12600 and are easy to calibrate and readjust to comply with ISO 9001 and GLP guidelines. Contactless coordination of the piston and the dosing cylinder results in a smooth sliding action with particularly little friction. Easy dismantling for cleaning. Equipped with replaceable filling valves. Autoclavable at 121°C.

Useful accessories include flexible discharge tubing, discharge tube for micro filter assembly or a dying tube. A remote Dispensing system simplifies dispensing of accurate volumes directly from drums and bulk refills and allows storage of the drum up to 10 meters (30 feet) away from the Dispensette®. Further features includes: - SafetyPrimeTM recirculation valve (optional)

Reduces risk of splashes caused by air bubbles during instrument priming and permits recirculation during priming to avoid reagent waste - Recalibration flag

Alteration of factory setting is automatically indicated by a red calibration flag. - Safety discharge system

Minimizes the risk of the medium being squirted out accidentally. - Rotating valve block

To allow the bottle label to face the user, the valve block can be rotated 360°. The 45 mm standard thread plus the included adapters fit com-mon lab bottles. - Discharge tube safety screw cap

Screw cap protects against reagent contact and is easy to attach and remove, even while wearing gloves. - Telescoping filling tube

Adjusts easily to different size bottles - without measuring or cutting.

Three different approaches to volume adjustment are available: - Digital Easy Calibration:

Digital display: especially easy to read, and dispensing volume can be set accurately and reproducibly (mechanical counter). Easy Calibration: Innovative technique for adjustment in seconds without tools. - Analog-adjustable:

Fast volume adjustment with analog slide. Simple calibration adjustment with supplied tool. - Fixed volume:

Fixed-volume for standard applications. Simple calibration adjustment with supplied tool.

The extensive range of models allows you to perform dosing taks in the most diverse applications:

Dispensette®III: the proven bottletop dispenser with its broad range of application

Dispensette®Organic: optimized for dispensing of organic solvents and concentrated acids Items supplied

1 Dispensette®, with performance certificate, conformity certified, operating manual, 1 dosing needle, 1 telescope-suction tube, recirculation valve SafetyPrime (optional), mounting tool and polypropylene adapter.

- Its very broad range of application permits dispensing of aggressive reagents, including concentrated acids such as H3PO4, H2SO4, bases like NaOH, KOH, saline solutions, as well as many organic solvents. For such reagents as fuming concentrated HCl and HNO3, for trifluoroacetic acid (TFA), tetrahydrofuran (THF), dichlormethane and peroxides, we recommend the Dispensette® Organic.

- The flowpath of the Dispensette® III consists of the following high-grade materials: borosilicate glass, ceramic, platinum-iridium, ETFE, FEP, PTFE and PFA. The discharge tube safety screw cap is PP.

- Operating limits: vapor pressure max. 600 mbar, viscosity max. 500 mm2/s, temperature max. 40°C, density max. 2.2 g/cm3.

2 Dispensette® III, analog-adjustable, conformity certified

3 Dispensette® III, fixed volume, conformity certified

Upon request, also available with individual fixed volume of your choice: available from 0.5 to 100 ml.

4 Dispensette® Organic

- The Dispensette® Organic (yellow color code) is ideal for dispensing of organic solvents including chlorinated and fluorinates hydrocarbons (e.g. trichloro-trifluoroethane and dichloromethane), or acids such as concentrated HCl and HNO3, trifluoroacetic acid (TFA), tetrahydofuran (THF) and peroxides. For bases and saline solutions we recommend the Dispensette® III.

- The lowpath of the Dispensette® Organic consists of the following high-grade materials: borosilicate, glass, ceramic, tantalum, ETFE, FEP, PFA and PTFE. The discharge tube safety cap is PP.

- Operating limits: vapor pressure max. 600 mbar, viscosity max. 500 mm2/s, temperature max. 40°C, density max. 2.2 g/cm3.

Dispensette®Organic, Digital Easy Calibration, conformity certified

5 Dispensette® Organic, analog-adjustable, conformity certified

6 Dispensette® III, fixed volume, conformity certified

Upon request, also available with individual fixed volume of your choice: available from 2 to 100 ml.

7 Accessories - Spare parts:

Dispensing tube with integrated discharge valve

Packs of one For Dispensette® III, red screw cap

For Dispensette® Organic, yellow screw cap

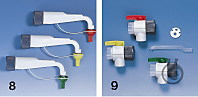

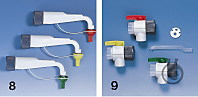

8 SafetyPrimeTM recirculation valve

9 Flexible discharge tubing

PTFE, coiled, approx. 800 mm long, with safety handle.

Not suitable for HF and peroxide.

For micro filter, FEP/PP. Pack of 1.

| Article | Order No. | |

| Discharge tube for Luer-Lock connection | 14 49 77928 | |

Not suitable for HF and peroxide.

PP, full plastic material – suitable for use in aggressive environment (e.g. acid fumes in the hood), rod length 325 mm, base plate 220 × 160 mm, weight 1130 g.

|

|

|